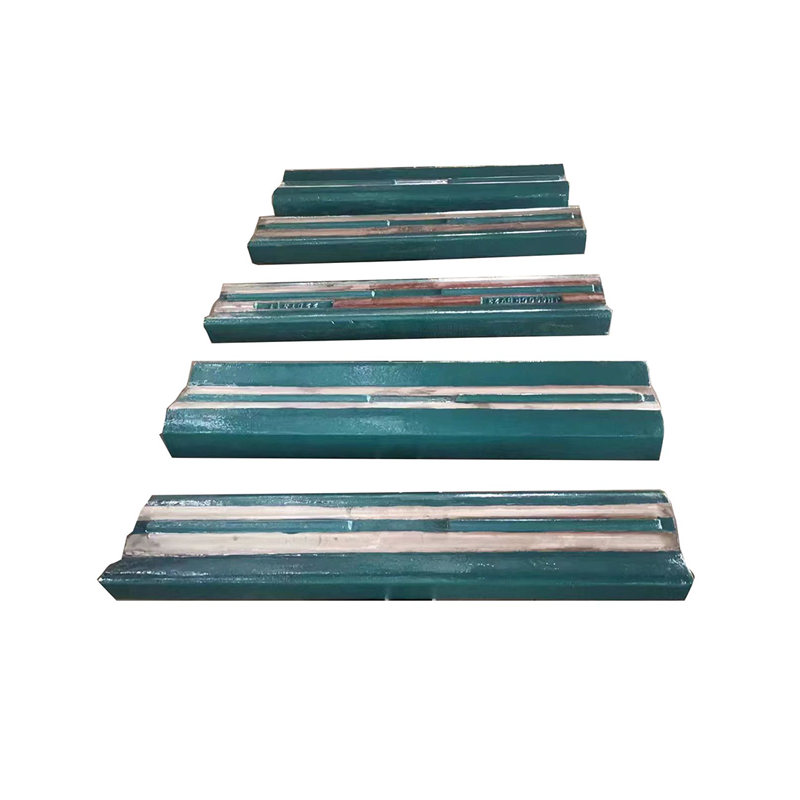

Big Discount Powder Separator Rotor - Flat hammer for building materials and metallurgy – Fiars

Big Discount Powder Separator Rotor - Flat hammer for building materials and metallurgy – Fiars Detail:

Technical Characteristics

a.Material:

The flat hammer is made of high chromium alloy, which has both strong wear resistance and good toughness, and it also has good high temperature resistance and corrosion resistance. With long service life, simple maintenance and the ability to crush large and hard materials, the flat hammer can adapt to a variety of materials.

b. Advanced manufacturing process:

● Customized design:The external furnace double refining technology effectively reduces the harm of harmful elements, inclusions and oxygen and hydrogen, and greatly improves the wear resistance and impact toughness of steel; Reasonable dimension and structure design, high casting accuracy, convenient installation and high reliability.

● Manufacturing process:Metamorphic treatment, grain refinement, improve the morphology and distribution of the carbide, and further improve the wear resistance and strong toughness of the flat hammer;

● Quality Control: Optimize the heat treatment process, so that the hardness of the flat hammer is uniform, and the impact wear resistance is stronger.

c. Strict inspection:

● Flaw detection should be performed for each product to ensure that there are no air holes, sand holes, slag inclusions, cracks, deformation and other manufacturing defects.

● Each batch of flat hammer is inspected randomly prior to delivery, including material tests and physical performance tests to ensure functional performance and provide laboratory test sheets.

Performance index

Hardness up to 60HRC-65HRC, set excellent abrasion resistance , high temperature oxygen resistance, thermal fatigue resistance, corrosion resistance, wear resistance and impact resistance in one.

Application

It is widely used in impact crusher for the mining, cement, metallurgy, chemical, infrastructure and other industries.

Product detail pictures:

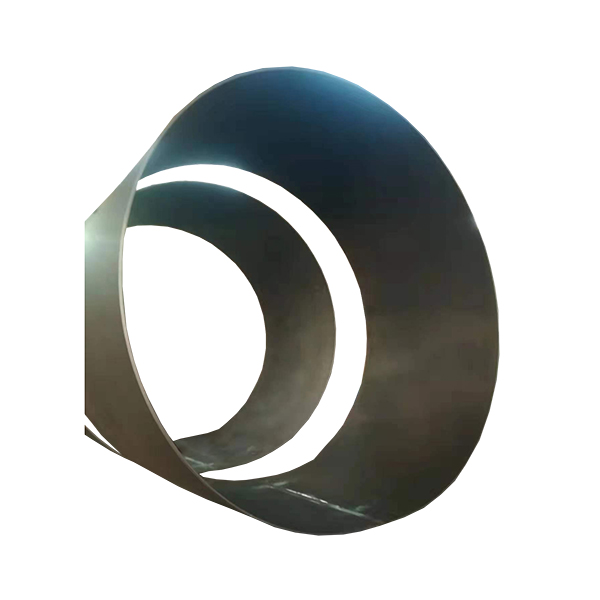

Related Product Guide:

We believe in: Innovation is our soul and spirit. Top quality is our life. Purchaser need is our God for Big Discount Powder Separator Rotor - Flat hammer for building materials and metallurgy – Fiars , The product will supply to all over the world, such as: Angola, Buenos Aires, Saudi Arabia, Being the top solutions of our factory, our solutions series have been tested and won us experienced authority certifications. For additional parameters and item list details, please click the button to acquire additional nformation.

This company can be well to meet our needs on product quantity and delivery time, so we always choose them when we have procurement requirements.