Excellent quality Vertical Mill Up Lining Plate - Grinding table liner of vertical mill – Fiars

Excellent quality Vertical Mill Up Lining Plate - Grinding table liner of vertical mill – Fiars Detail:

Technical Characteristics

Vertical mill is an ideal large-scale grinding equipment, widely used in cement, power, metallurgy, chemical, non-metal mining and other industries. It integrates crushing, drying, grinding and graded transportation, with the characteristics of high grinding efficiency, large energy saving range, reliable operation and convenient maintenance, and can grind the block, granular and powder raw materials into the required powder materials. The rotation of the vertical mill grinding plate drives the rotation of the grinding roll, squeezing the material. The crushed fine powder is brought into the dust collector from the top to the bottom by the wind, and conveyed to the silo through the slide chute and the elevator.

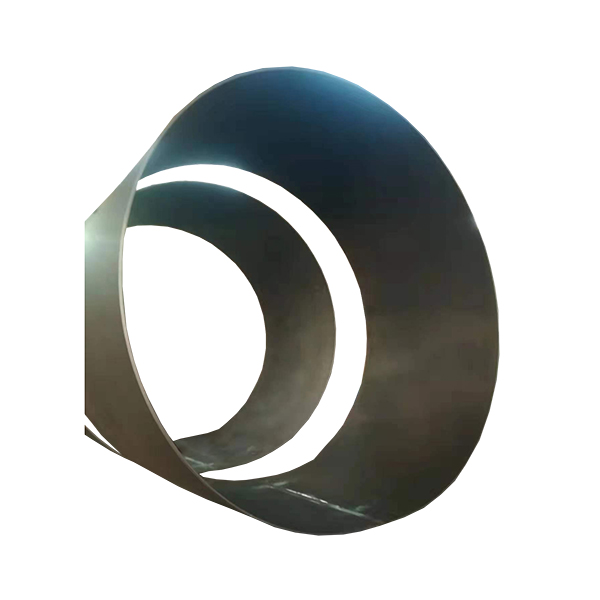

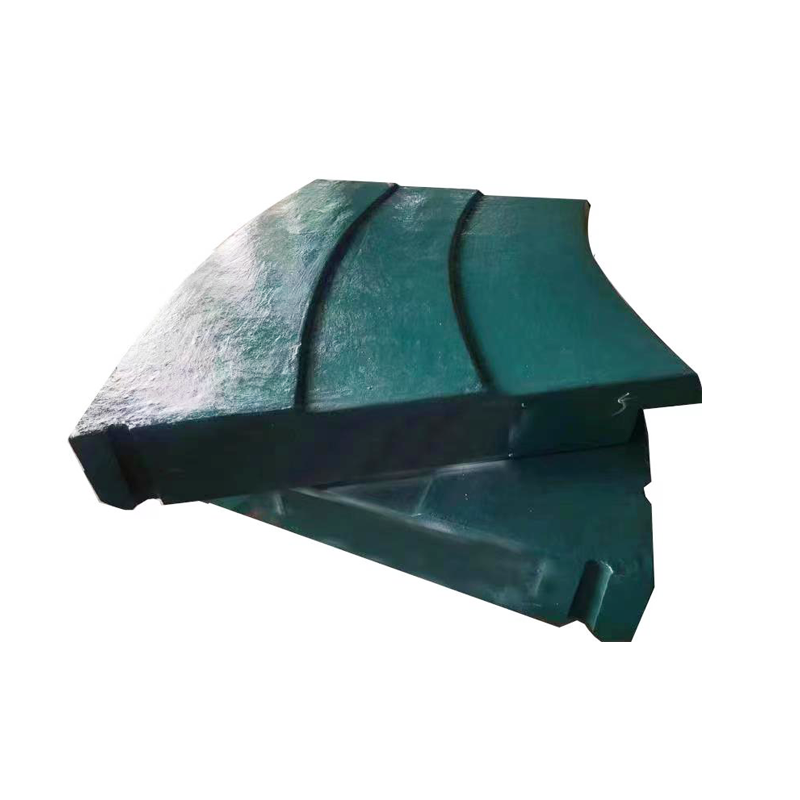

The grinding table liner and the roller sleeve of the vertical mill are wear-resistant parts of the vertical mill, which are mainly responsible for contacting with materials and producing extrusion pressure. The grinding table liner is made of high chromium cast iron with strong hardness and wear resistance, which can be used for the grinding of limestone, pulverized coal, cement, slag and others.

a. Advanced manufacturing process:

● Customized design: V method vacuum casting, casting quality is good, high precision, can be cast according to the size of user drawings.

● Manufacturing process: The heat treatment process is controlled by the computer program which make the liner with uniform texture and excellent performance. The fitting surface is fine turning to ensure closely matched, which also ensures the reliability and operation rate of the equipment.

● Quality Control: Smelting steel water shall be discharged after qualified spectral analysis; the test block for every furnace shall be heat treatment analysis, and the next process shall proceed after the test block is qualified.

b. Strict inspection:

● Flaw detection should be performed for each product to ensure that there are no air holes, sand holes, slag inclusions, cracks, deformation and other manufacturing defects.

● Each product is inspected prior to delivery, including material tests and physical performance tests to ensure functional performance and provide laboratory test sheets.

Performance index

Material hardness, impact resistance: hardness 55HRC-60HRC;

Impact toughness Aa≥ 60j /cm².

Application

It is widely used in the vertical mill of power, building materials, metallurgy, chemical, non-metal mining and other industries.

Product detail pictures:

Related Product Guide:

To be a result of ours specialty and repair consciousness, our corporation has won a good popularity amid consumers everywhere in the environment for Excellent quality Vertical Mill Up Lining Plate - Grinding table liner of vertical mill – Fiars , The product will supply to all over the world, such as: Ecuador, Austria, Colombia, Our solutions are produced with the best raw materials. Every moment, we constantly improve the production programme. In order to ensure better quality and service, we now have been focusing on the production process. We have got high praise by partner. We are looking forward to establishing business relationship with you.

Good quality and fast delivery, it's very nice. Some products have a little bit problem, but the supplier replaced timely, overall, we are satisfied.