Manufacturer of Weigh Apron Feeder - Crusher hammer for building materials and mining – Fiars

Manufacturer of Weigh Apron Feeder - Crusher hammer for building materials and mining – Fiars Detail:

Technical Characteristics

a.Various types:

Based on the different type of the raw materials, the different type of hammer can be selected: Ultra high manganese hammer head, ultra high manganese composite cast hammer head, double metal composite hammer head, high manganese steel inlaid alloy block hammer head, high manganese steel inlaid alloy rod hammer head, modified high manganese steel hammer head, medium alloy hammer head. In addition to the material and heat treatment process, the dimension of the hammer also has a great impact on the service life, the design of the dimension of the hammer can be according to the difference of the equipment use, broken material and other working conditions which to increase the service life.

b. Advanced manufacturing process:

● Customized design: V method vacuum casting, mold open by computer. Advanced casting technology, high precision products

● Manufacturing process: Water quenching heat treatment process controlled by computer program, hole-boring by boring machine, machining surface by lathe.

● Quality Control: Smelting steel water shall be discharged after qualified spectral analysis; the test block for every furnace shall be heat treatment analysis, and the next process shall proceed after the test block is qualified.

c. Strict inspection:

● Flaw detection should be performed for each hammer to ensure that there are no air holes, sand holes, slag inclusions, cracks, deformation and other manufacturing defects.

● Each batch of flat hammer is inspected randomly prior to delivery, including material tests and physical performance tests to ensure functional performance and provide laboratory test sheets.

Performance index

Material hardness, impact resistance: hardness HB210~230;

Impact toughness Aa≥200j/cm².

Application

It is widely used in the hammer crusher of mining, cement and metallurgy industry.

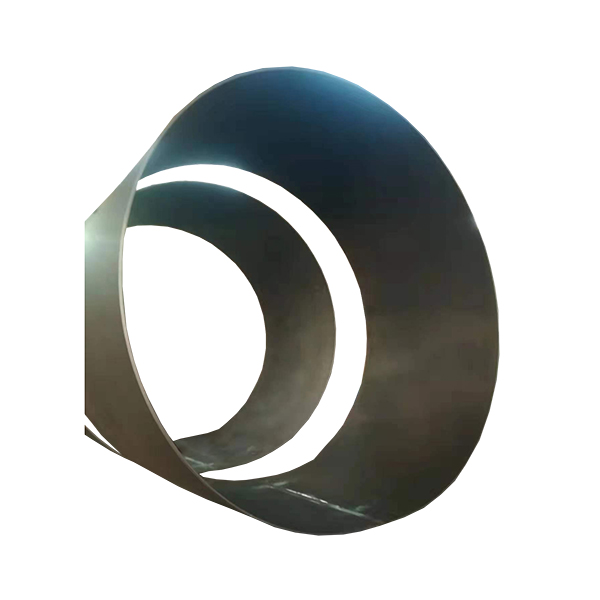

Product detail pictures:

Related Product Guide:

We pursue the administration tenet of "Quality is remarkable, Services is supreme, Status is first", and will sincerely create and share success with all customers for Manufacturer of Weigh Apron Feeder - Crusher hammer for building materials and mining – Fiars , The product will supply to all over the world, such as: Amsterdam, Swaziland, Montpellier, Our company always concentrate on the development of the international market. We now have a lot of customers in Russia , European countries, the USA, the Middle East countries and Africa countries. We always follow that quality is foundation while service is guarantee to meet all customers.

This is a very professional and honest Chinese supplier, from now on we fell in love with the Chinese manufacturing.