The plate chain bucket elevator is a widely used vertical lifting equipment, which is suitable for vertical conveying of medium and large pieces and abrasive materials (such as limestone, cement clinker, gypsum, lump coal) with material temperature below 250℃. The plate chain bucket elevator adopts material inflow type feeding and gravity induced discharge. The machine adopts fully sealed casing, almost no return material phenomenon, so it has less reactive power loss, low noise, long life, and high production capacity and low energy consumption.

I. Model and scope of application

NB series bucket elevator is composed of NBC type, NBE type, NBS type, NBH type and so on. Through the combination of different types of hoppers and chains, different types of materials can be conveyed.

NBC Type: suitable for lifting bulky and highly abrasive materials at medium and low speeds;

NBE Type: The improved hopper type can have greater lifting capacity than the NBC type; suitable for lifting bulky and highly abrasive materials at medium and low speeds;

NBS Type: Suitable for lifting powdery materials and small granular materials at low speed;

NBH Type: High speed bucket elevator developed from NBS type; due to the high operating speed of NBH type elevator, a smaller elevator than NBS type can be used with the same lifting capacity, which has good economy. In combination with different types of hoppers, different types of materials can be conveyed at high speed.

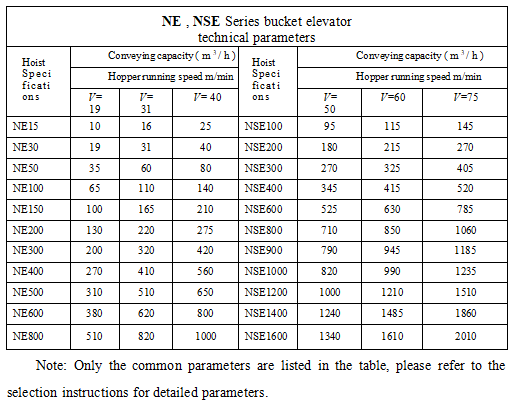

NE series bucket elevator consists of two types: NE type and NSE type. The NE model lifts materials at low and medium speeds, while the NSE model lifts materials at high speeds based on the NE model. Compared with NB series, the efficiency of NE series is lower, but its versatility is better。

NB , NE series plate chain bucket elevator adopts precision-made plate bushing roller chain as the traction chain, It has the characteristics of large lifting capacity, high lifting height, stable and reliable performance, and easy maintenance. It is suitable for conveying raw materials or semi-finished materials in building materials , cement, chemical industry, metallurgy and other industries.

II. Performance characteristics

1. Fast lifting speed: The lifting speed of the high-speed plate chain hoist can reach 90m / min . The conveying capacity of the conveyor is large, the structure size is small, and the economy is good.

2. The traction chain adopts short pitch and special structure to reduce the impact force of the meshing of the chain and the sprocket, It runs very smoothly.

3. The traction chain processed by precision manufacturing technology has the excellent characteristics of high tensile strength and long service life.

4. The hoist has a compact structure, good sealing performance and convenient maintenance.

5. The combination of chain and hopper with various structural forms can be selected according to different situations. The layout is flexible and diverse.

6. The middle section adopts the structure of pressed ribs, which effectively increases the strength and rigidity of the middle section, and can adapt to the requirements of large conveying capacity and lifting height.

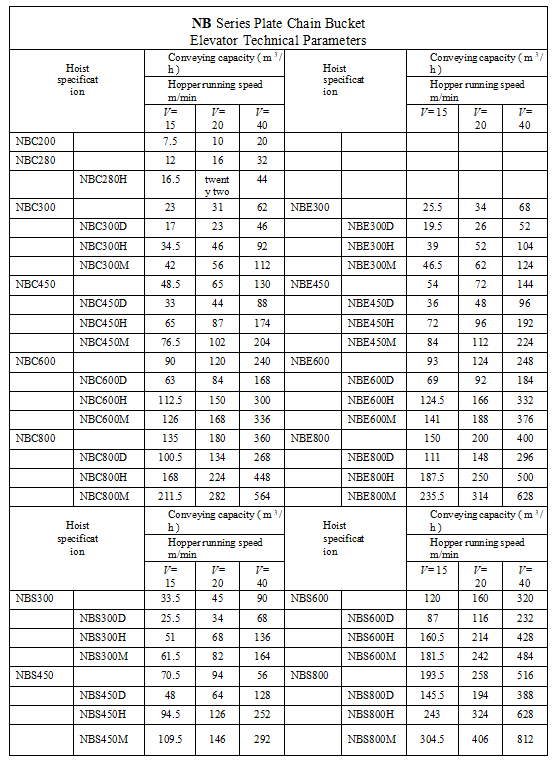

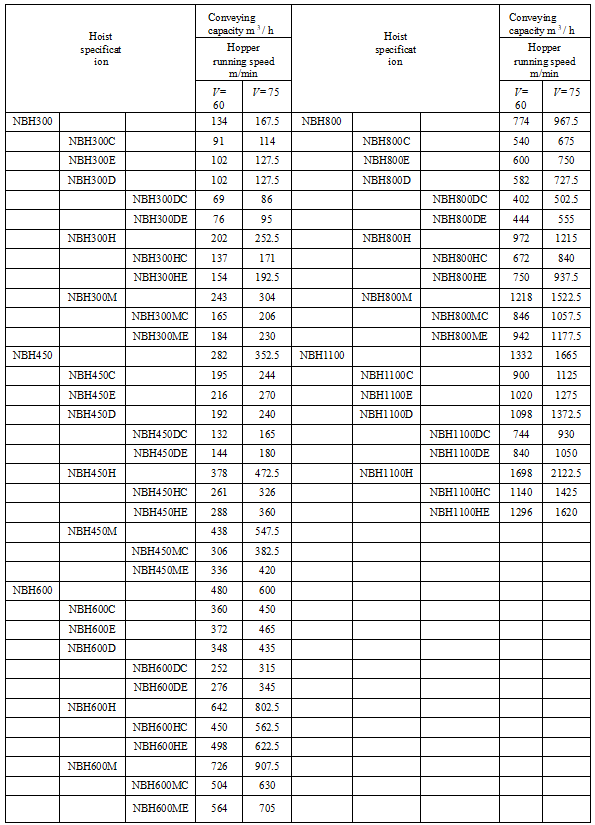

III. Specification list

IV. Chain bucket elevator structure

The chain bucket elevator is composed of running parts, driving device, upper device, middle casing and lower device .

1. Running parts - composed of hopper and special leaf chain, NE30 and the lower adopts a single row chain, NE50-NE800 Adopt double-row chain.

2. Driving device—it is driven by a variety of driving combinations ( according to the actual needs of users ) , and the driving platform is equipped with inspection frames and railings. The driving device is divided into two types: left installation and right installation: facing the feeding port, the driving device power is on the left side of the casing is the left installation; facing the feeding port, the driving device power is on the right side of the casing is the right installation.

3. The upper device - equipped with track ( double row chain ) , backstop, and anti-return rubber plate at the discharge port.

4. Intermediate section - some intermediate sections are equipped with tracks ( double chains ) to prevent the chain from swinging during operation.

5. Bottom device—installed with automatic tensioning device.

V. Main parts

Post time: Jun-09-2023